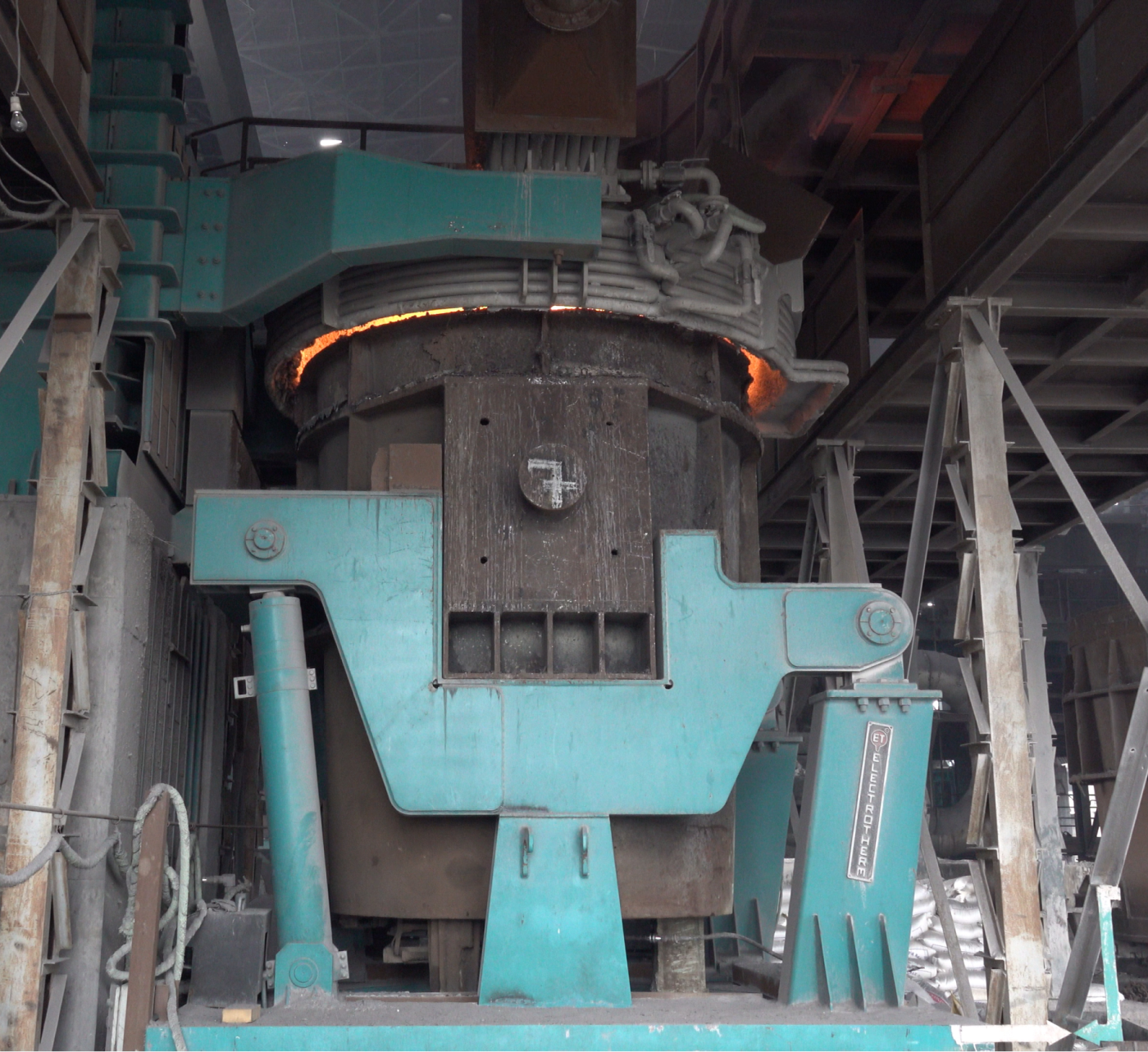

Advance Technology – Ladle Refining Furnace

Maharashtra’s First & Only Company to adopt LRF – Providing the Pure Quality of steel”

Why LRF?

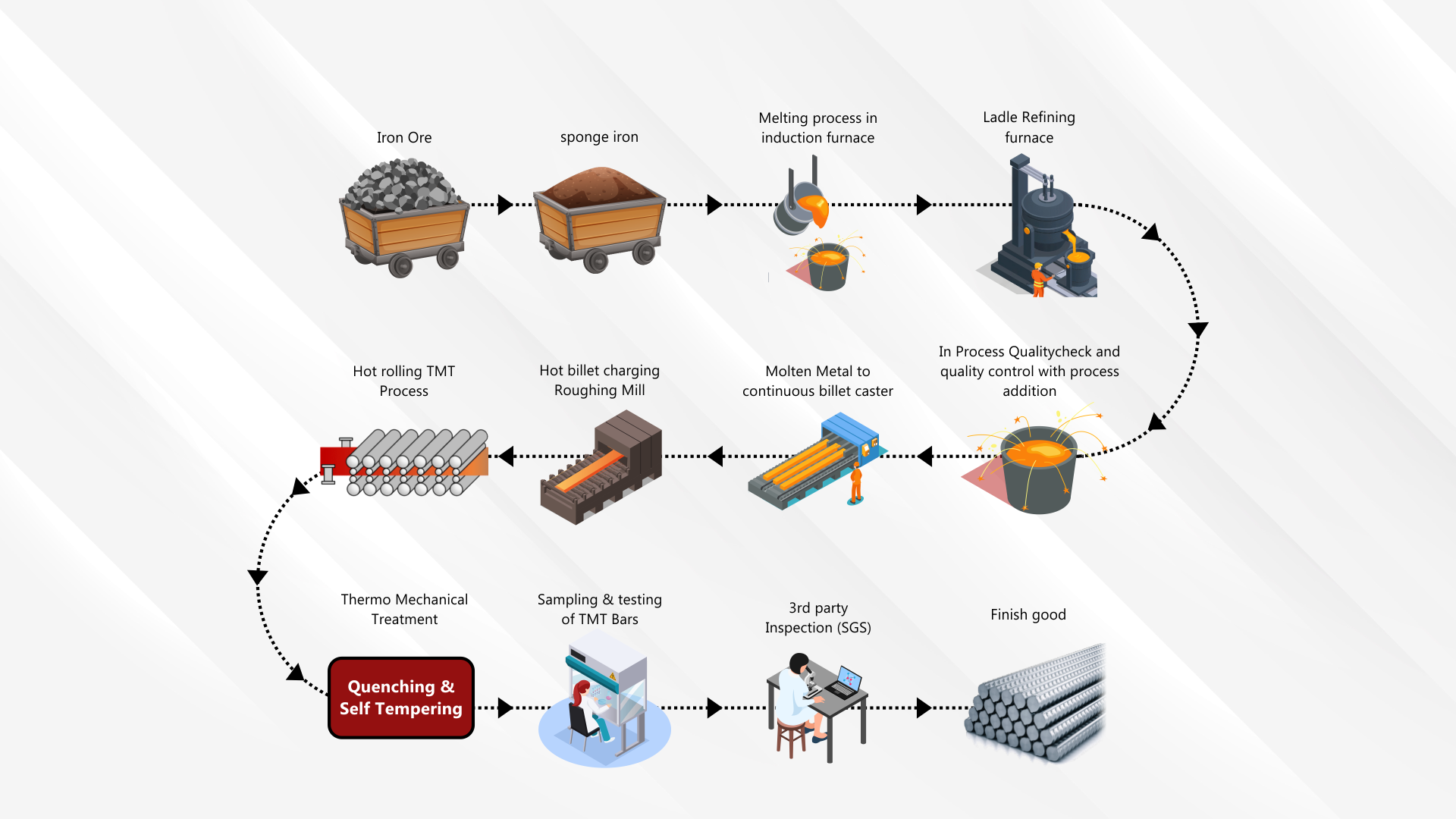

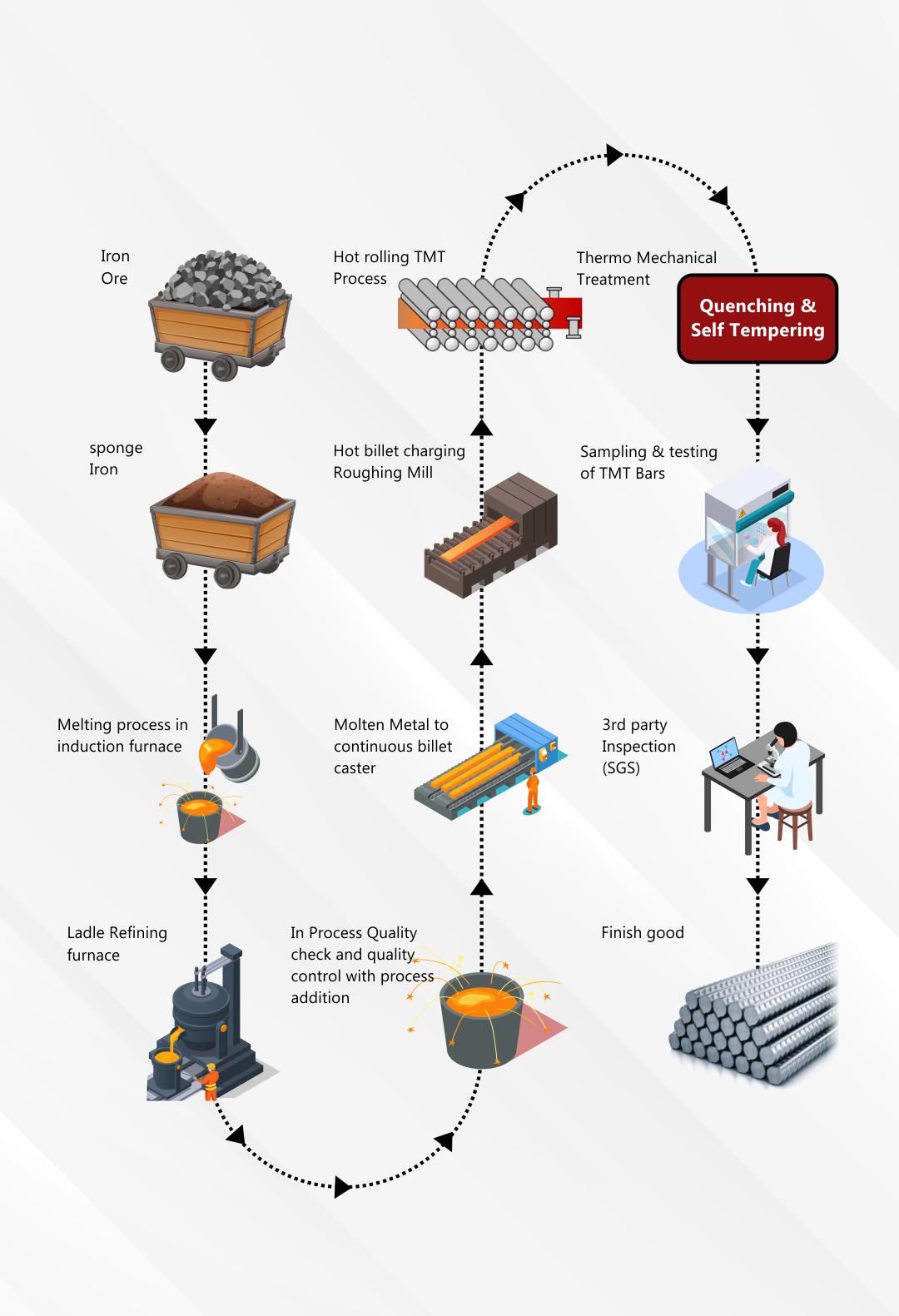

- High quality of raw material is melted in induction furnace which also has a few gases. In order that all these gases completely escape and impurities are totally removed, molten liquid is transferred into Ladle Refining furnace where additional heat is provided.

- A Ladle Refining Furnace is used to raise the temperature and adjust the chemical composition of molten metal.

- With the help of LRF, two crucial elements like Sulphur & Phosphorus can be controlled in exact proportions to produce a better quality of steel.

- Additionally, LRF treatment helps float inclusions in steel and removes dissolved gases.

- Induction furnace + LRF lend high quality TMT bars, specially of 500D grade needed for large scale infrastructure projects.