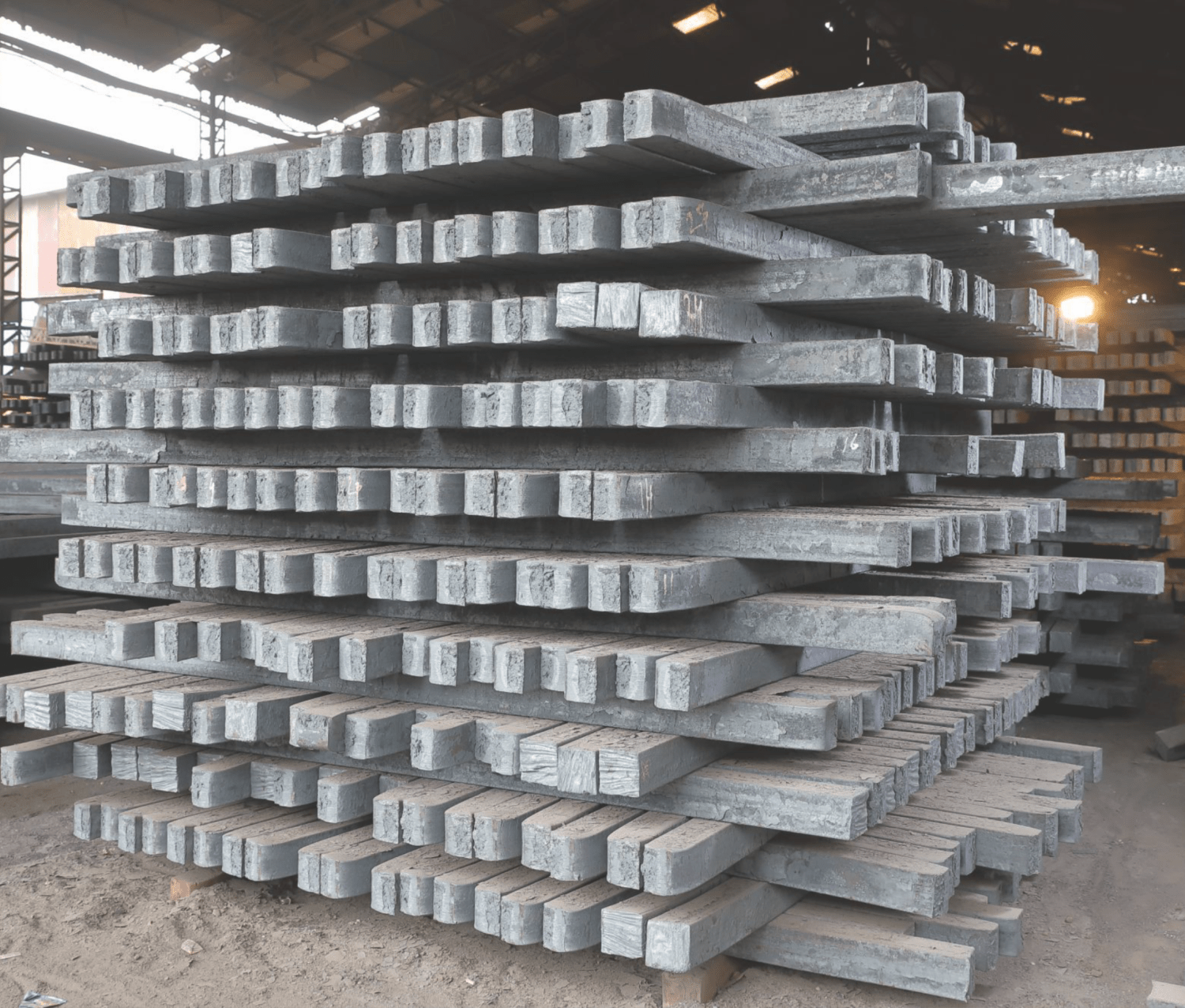

Billets

High Quality Billets in a cross section of 130X130X7000 mm are used for manufacturing of Metaroll TMT Bars.

What are Billets?

Billets are semi-finished steel products characterized by their square or rectangular cross-sections. They are typically produced through a casting or hot rolling process and are widely used in various industries such as construction, automotive, machinery, and more. Billets serve as the starting material for shaping and transforming steel into different products like bars, rods, wire, pipes, and structural components.

Billet Production Process

Casting Method

In the casting method, liquid steel is poured into molds to create billets. This process involves carefully controlling the temperature and composition of the molten steel to ensure desired properties in the final product. Once the steel solidifies within the molds, the billets are removed and undergo further processing to achieve the required dimensions and surface finish.

Hot Rolling Method:

In the hot rolling method, a large steel slab is heated and passed through a series of rolling mills to reduce its thickness and form it into a billet shape. This process not only imparts the desired shape to the billet but also refines its internal structure, resulting in improved mechanical properties.

Key Advantages of Billets

Versatility: Billets offer versatility in steel production as they can be further processed into a wide range of products, accommodating various industrial applications.

Customizability: The dimensions, length, and surface finish of billets can be customized according to specific requirements, ensuring a perfect fit for the intended steel product.

Strength and Durability: Billets are manufactured using high-quality steel, providing excellent strength and durability to the final products made from them.

Cost-Effective: Billets serve as a cost-effective option in the steel production process due to their efficient manufacturing techniques and ability to be transformed into multiple end products.